Improve Your Protein Purification Process Economy with CHT Ceramic Hydroxyapatite XT Media

CHT Ceramic Hydroxyapatite XT Media is designed for repeated use and exceptional resolution. It combines exceptional functionality with a long column life to help achieve high productivity and improved process economics. See how CHT XT can improve your protein purification.

Introducing the NGC™ Fraction Collector for Discovery to Process-Scale Protein Purification

The newly launched NGC™ Fraction Collector, together with ChromLab™ 5.0 Software, have enhanced the functionality of the NGC Chromatography System to provide the flexibility and collection capacity needed for any application, from discovery to scale up. See how the NGC System can help you improve your protein purification process.

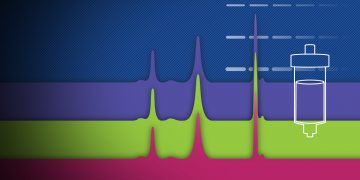

Minimizing On-Column Monoclonal Antibody Aggregate Formation

The formation of aggregates is a common but highly undesirable occurrence during monoclonal antibody purification. See how on-column aggregation is dependent on the type of resin used and how one particular high-resolution cation exchange resin allows for the lowest proportion of aggregate formation.

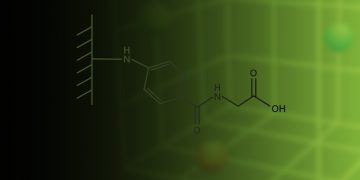

Practical Experimental Design for Mixed-Mode Resins

Could you be missing opportunities to make the most of your time spent on protein chromatography experiments? Learn more about how Bio-Rad uses design of experiments (DoE) and our mixed-mode resin, Nuvia™ cPrime™, to optimize process-scale protein purification.

An IMAC Resin for a Highly Productive Histidine-Tagged Protein Purification Process

One of the advancements in protein purification has been to tag the protein of interest with a short sequence that can bind to an immobilized matrix and aid purification. Bio-Rad’s new IMAC resin offers a host of advantages for the purification of histidine-tagged proteins. Learn more about this resin and see how it can enhance the efficiency of your protein purification workflow.

Modern Improvements to Classic Technologies: Innovating Electrophoresis and Chromatography Upstream of Protein Characterization to Speed Up Research

When testing new drug therapies, it is essential to know the identity of the protein being tested. Chromatography is a commonly used technique to separate complex biological mixtures and isolate proteins of interest prior to downstream characterization. Learn more about how automating chromatography and stain-free technology are helping to save time and effort in protein purification.

From Optimization to Automation: Multidimensional (Multi-D) Histidine-Tag Protein Purification

A well-designed multidimensional (Multi-D) chromatography process, which utilizes optimized individual column methods, can help automate multistep protein purification processes. This can help you save time and increase productivity. See how you can use Multi-D chromatography to expedite the purification of polyhistidine-tagged proteins when using a typical capture, intermediate, and polish purification workflow.

Coupling Automated Chromatography with Faster Confirmation of Purity and Yield

We’ve combined the chromatography process with purity and yield assessment using stain-free gels to shorten and optimize your protein purification workflow. See how it’s done.

Attaching a Dynaloop to the NGC™ Chromatography System

This video describes the three main steps in attaching a DynaLoop Sample Loop to the NGC™ Chromatography System to enable the injection of larger sample volumes: connecting the DynaLoop Sample Loop to the NGC Chromatography System, priming the DynaLoop Sample Loop, and creating a method in ChromLab™ Software.

Calibrating the pH Valve on the NGC™ Chromatography System

The NGC pH valve provides real-time, in-line monitoring of buffer pH. In this video, you’ll learn how to connect the pH valve to the NGC System, add it to the flow path, and calibrate the valve using buffers at two different pH values. Features of the pH valve include accessible calibration ports and easy bypass of the probe when the NGC System is being cleaned.