One-size-fits-all solutions cannot address the full range of molecular biology needs in areas such as biotech, biopharma, or molecular diagnostics. When your requirements exceed the existing offerings of reagents and plastics on the market, Bio-Rad can partner with you and provide custom solutions.

For a deeper look into these customization opportunities, we spoke with Anna Lai, manager of Bio-Rad’s custom reagents program, and Jennifer Placek, who manages the company’s custom plastics. Our conversation revealed seven ways in which customization can simplify the development of a customer’s new PCR or qPCR product by improving convenience and selection, while ensuring high quality and cost effectiveness.

1

Speed of query response

Lai explained how the program’s reagent request interface is designed for ease and speed. “It offers various options for reagents to get the process started, and the requestor can typically expect to hear from Bio-Rad within 48 hours. We also simplify the partnership process with templates for licensing and nondisclosure agreements (NDAs).”

Placek added that, similarly, the response time to the PCR plastics intake form is just 24–48 hours. “Customers can either fill the form out themselves or work with their Bio-Rad sales representative. Either way, we’ll have the information we need to accurately assess their request.”

2

The latest options for PCR reagents and plastics

We asked about the type of custom reagent options available, and what useful features they include. “We offer custom packaging, sizing, and labeling, including 2-D barcodes for product tracking,” Lai said. “And of course, we make sure our reagent processes adhere to good manufacturing practices, also known as GMP. With Bio-Rad’s custom reagent format, customers can leverage over 70 years of manufacturing experience and our supplier reputation. They can access the highest quality product components without the high cost of developing them on their own.”

Placek described the many options available for customizing 96- or 384-well PCR plates, which even include changing the color of the shell. “Customers can obtain Hard-Shell PCR Plates that have specialized barcodes such as LIMS-specific or 2-D barcodes. They can also have us brand them with their own logo, which is ideal for plates intended for an assay kit. And customers can choose different packaging configurations for their product with documentation and label specifications.”

3

Faster time to market

Speed to market is often a critical factor in commercial success, and as a PCR partner, Bio-Rad can help ensure speed by aiding the customer’s unique PCR process. As Lai noted, “Customers can focus on their assay without the distraction of creating all the components. Making an entire product in-house can add years to the process.”

She also emphasized how quick access to quality manufacturing saves crucial time. “When a customer needs an optimized supermix for their product, the process of developing, optimizing, and validating its manufacture in a GMP format is an overwhelming amount of work. But Bio-Rad already has the full complement of GMP controls in place and can quickly apply them to custom products.”

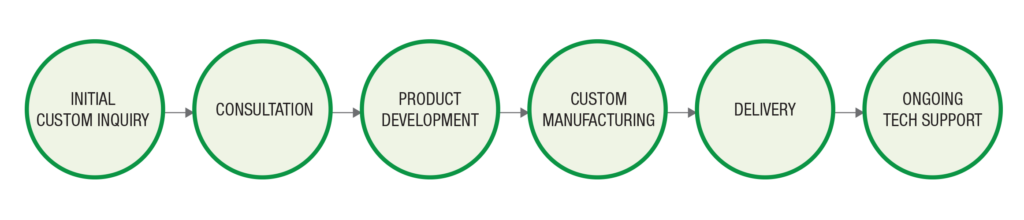

Stages of the custom PCR reagents and plastics programs. These custom programs begin with an initial inquiry and consultation before proceeding into product development. Following development, the custom products are manufactured and delivered to the customer, and ongoing tech support is available for any post-delivery concerns.

– Anna Lai, Bio-Rad

Similarly, Placek pointed out that Bio-Rad, as an established leader in plastics, can start with its proven off-the-shelf plates and customize them to exacting specifications. The popular Hard-Shell Plates are a great example for customers using automation. “Hard-Shell Plates have superior performance due to their two-component rigid frame, which doesn’t warp or bend, enabling superior well-to-block contact for precise thermal transfer. These features are critical in lowering the risk of automation failures.”

4

Access to Bio-Rad’s proprietary technology

Another advantage of Bio-Rad’s custom PCR reagents program is access to advanced products, such as Bio-Rad’s proprietary enzymes and buffers. Lai put it this way: “Bio-Rad is known for its excellent enzymes and buffers. Now we can facilitate the customer’s ability to build their own kits with these reagents, giving them the benefit of our proprietary technology.”

For PCR plastics, Placek reiterated that Bio-Rad offers customization of their exclusive Hard-Shell Plates.

5

Cost controls for custom manufacturing and packaging

Placek discussed how Bio-Rad’s established products are manufactured at a high volume to make best use of labor resources and keep overhead costs lower, and those cost savings carry over to customization projects. “The cost for a customer to brand a conventional plate can be much higher than having Bio-Rad, as the plate manufacturer, provide that service for them.”

Likewise, from Lai’s perspective, the cost savings in custom reagents are related to the manufacturing process — including the packaging aspect. “We have the manufacturing capacity and scale to manage reagent pricing and packaging.” Even a customer who saves money by having their reagents made for them can still encounter significant costs if they opt to do their own packaging.

6

Quality assurance for custom products

Bio-Rad is also able to ensure both the quality and consistency of custom PCR plastics and reagents alongside cost-effective pricing.

Lai notes, “We have implemented ISO and GMP certifications to ensure the highest level of quality. Ultimately, it gives the customer further assurance that Bio-Rad’s custom program is superior to their in-house development and manufacture.”

Placek echoed that quality control can pose a significant challenge when customers try to customize plastics in-house. “Barcoding often demands a high labor cost for the customer, on top of the time sourcing the correct barcode, and finally the challenge of quality control checks. As the manufacturer, Bio-Rad can implement inline quality control (QC) during manufacturing as well as final QC.”

And unlike manufacturers that produce lower-cost plastics that are often inferior in quality, Bio-Rad can better monitor quality while enabling a cost-effective solution. As Placek explains, “Bio-Rad can pivot quickly and address questions from customers if they see anything out of the norm. With a plastics distributor who is not also an established, high-quality manufacturer, the quality control just isn’t there.”

7

Timely delivery

Finally, the question of project delivery times is important. Lai reiterated that this is part of the initial discovery with customers. “We work very closely with the customer to ensure the delivery timing meets their needs.” Placek agreed. “Customer communication occurs throughout the process, so the customer is well-informed about the status of their project and its delivery.”

These seven key points show how the custom PCR reagents and plastics programs offer a new avenue for customers in need of specialized components for their products. Customers can leverage Bio-Rad’s history as an industry-leading life sciences manufacturer that can offer material performance, cost management, and adaptability to evolving applications.

Customization can lead to new products that empower researchers to achieve better results and advance their studies by eliminating the limitations imposed by generic, non-customized solutions.

Explore how customized PCR reagents and plastics can accelerate your product.